Extrusions For LEDs – when should I use aluminium LED profiles?

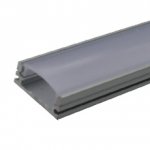

By housing your LED tape into an extrusion, you can create a more ‘finished’ look when compared to the unhoused PCB – which is ideal if the product is installed in a location where it will be clearly visible.

What are the benefits of LED Extrusions?

InStyle LED stocks a range of extrusion profiles, each offering different advantages. They include our optic lens extrusion, which actually ‘throws’ light further by narrowing the LED tape’s light beam – and our recessed extrusion, which adds a plush finish to your LED strip lights.

What’s the difference between LED Extrusions & LED Profiles?

There is no difference. The terms ‘aluminium extrusion’ and ‘aluminium profile’ are interchangeable.

What types of LED Extrusions are available?

Where to use LED Extrusions

Our aluminium extrusions can enhance and improve all kinds of LED strip light installations. They are an ideal addition in restaurants, hotels, bars, and clubs.

What is the length of an LED Extrusion?

As well as our standard LED strip lights, we also offer splash-proof (IP65) or fully waterproof (IP67) tapes, sealed with heatshrink coatings.

If you choose to cut one of our IP67 tape lengths yourself, it will no longer be guaranteed water resistant… but you can fully reseal the tape back to its original protection rating by using a heat gun and heatshrink.

How to install an LED Extrusion

Extrusions can be fixed in place using countersink screws, straight into the extrusion. Alternatively, you can purchase fixing brackets if you prefer. These can be attached in place, and once they are in position, your extrusion can be clipped onto them.